Parabolic Leaf Springs9443200102-00 (S. H.) , 9443200102-00 (C. H.)

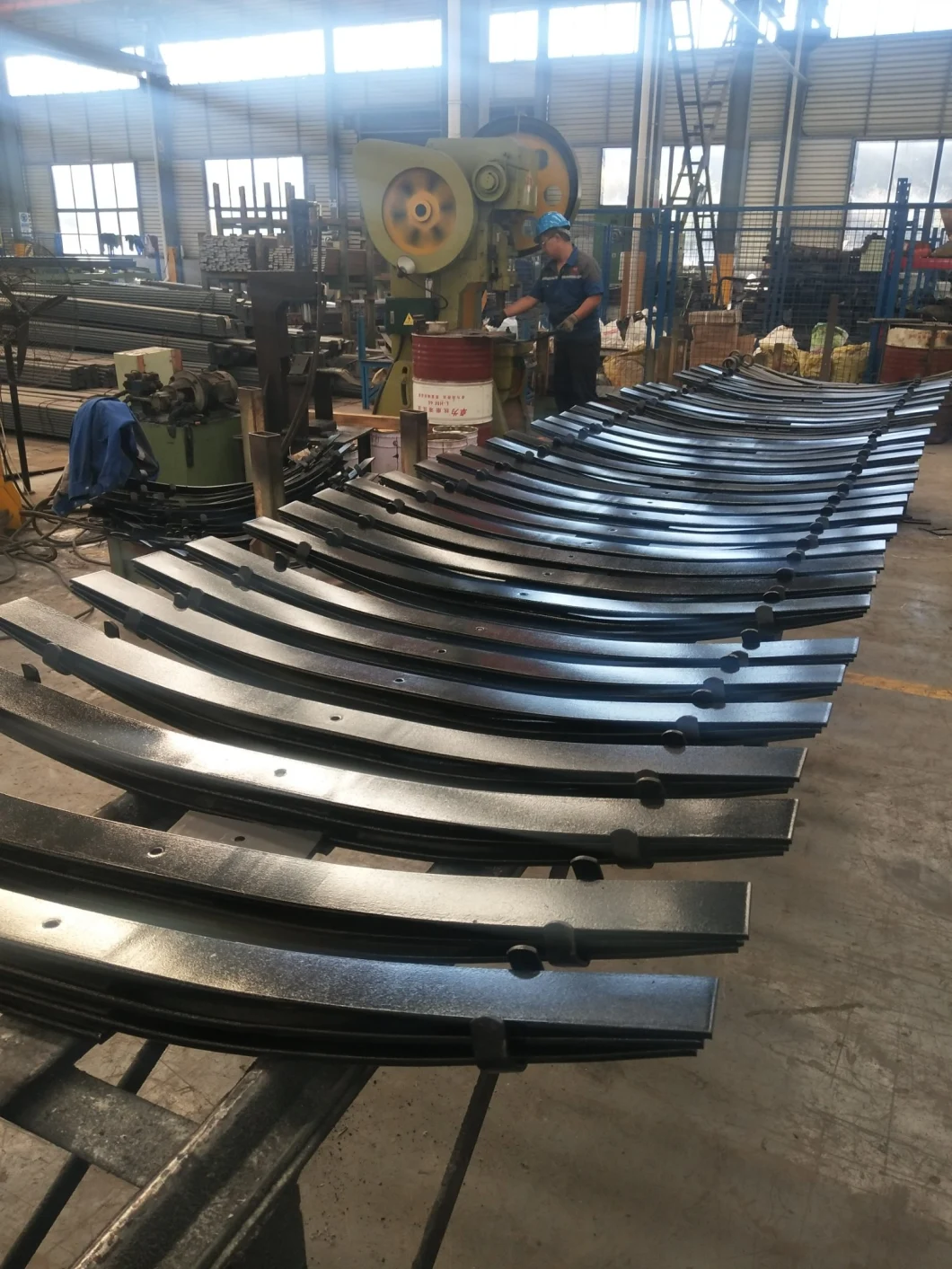

Overview This is our one of workshops. The leaf springs were finsihed baking paint and were waiting for being installed.

Description

Basic Info

| Warranty | 2 Years |

| Material | Carbon |

| Certification | ISO/TS16949 |

| Car Make | Benz, Honda, Toyota, Jeep, Nissan, Ford, Volvo, Mazda |

| Position | Front |

| OEM | Yes |

| Type | Suspension Spring |

| Transport Package | Pallets |

| Specification | SUP9, SUP10, 50CrV4, SUP11 |

| Trademark | QDHEROSUN |

| Origin | China |

| HS Code | 7320102000 |

| Production Capacity | 100000 Tons Per Year |

Product Description

This is our one of workshops. The leaf springs were finsihed

baking paint and were waiting for being installed.

| Working life | 80,000 Hours | Voltage | DC 12V-14V |

| Color | Red, shinning black, dark black, grey, | Application | Heavy Duty Dumping Truck Trailer Suspension |

| Types | Conventional / Parabolic / Z Type Leaf Spring/ Air Linker/ Small leaf spring | Certification | ISO9001; TS16949; COC; PVOC; CIQ; SONCAP; BV; C/O; FORM E. |

| Components | Leaf, clip, center bolt, U bolts | Warranty | 2 years |

| Item Name | Leaf Spring | Function | shock absorption |

| Raw Material | Spring Steel | MOQ | 5 Tons |

| Supply Capacity | 40,000 Tons per Month | Delivery Time | around 3-4 weeks |

| Package | By Pallet; 25T in 1X20FCL. | Port | Xingang/Tianin |

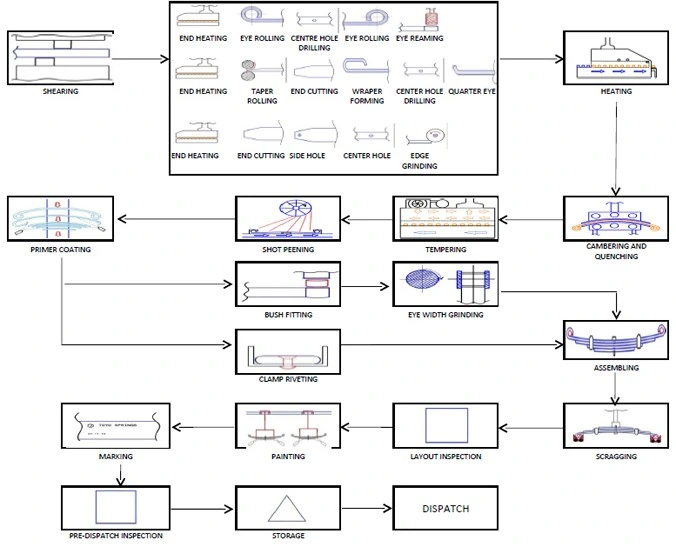

Manufacturing Process

- 1. Shearing of flat bar

- 2. Center hole punching / Drilling

- 3. End heating process forming - Eye Forming / Wrapper Forming - Diamond cutting / end trimming / width cutting / end tapering - End punching / end grooving / end bending / end forging / eye grinding - Center hole punching / Drilling / nibbing

- 4. Heat Treatment - Heating - Chamber forming - Hardening - Quenching - Tempering

- 5. Surface preparation - Shot peening / Stress peening - Primary painting

- 6. Eye bush preparation process - Eye reaming / eye boring - Bush insertion - Bush reaming 7. Assemble - Presetting & load testing - Finish painting - Marking & packing

INSPECTION

Our Advantages

Good quality, good cooperation and good credit.

FAQ

Q. How do you pack ?A. First packing according to cutomer's requirements. If no requirements, we first put leaf springs in pallet, then fix iron packing belts, and then stretch plastic film around pallet. At last put shipping marks paper on the pallet.Q.Whats the size of raw material do you use?A.Steels SUP7 SUP9 SUP9A SUP10 60Si2Mn 51CrV4 SUP11, SUP11A, SUP13.Thickness from 6mm to 56mm and width from 44.5mm to 150mm, mainly according to customer's requirements.Q.Can we custom our own logo or label on this product?A.Yes,you can. We support logo print&stamping &label print. Q.What is your lead time?A. Our lead time is 20~30 days.

Our Contact

Send now